Sonobond’s ultrasonic technology provides an ultrasonic system capable of welding the tin-coated wires and terminals essential to electrical applications for high-temperature, high-humidity and other environmentally challenging conditions. Tin-coated copper wiring is preferred for marine motors and electronics, appliances, solar panel wiring and some automotive applications. Sonobond’s ultrasonic units can achieve consistently reliable welds that remain highly conductive without sacrificing the protective properties of the tin coating.

Sonobond’s ultrasonic technology provides an ultrasonic system capable of welding the tin-coated wires and terminals essential to electrical applications for high-temperature, high-humidity and other environmentally challenging conditions. Tin-coated copper wiring is preferred for marine motors and electronics, appliances, solar panel wiring and some automotive applications. Sonobond’s ultrasonic units can achieve consistently reliable welds that remain highly conductive without sacrificing the protective properties of the tin coating.

Sonobond’s Wedge-Reed System was specifically designed for high impedance metal welding. It combines low vibratory amplitude with high vibratory force, directed in a shear mode parallel to the interface of the materials to be welded. The shear mode is essential for ultrasonic metal welding.

The Wedge-Reed System uses a vertical, vibrating reed, driven by a wedge-shaped coupler and transducer assembly that’s perpendicular to the reed. With the line of static clamping force directly above the parts to be welded, high clamp force can be achieved without bending stress or stalling. The tin coating is dispersed and the copper wire is welded without compromising the conductivity of the copper.

By definition, the impedance is proportional to vibratory force and inversely proportional to vibratory distance or amplitude. With Sonobond’s Wedge-Reed System, the vibratory amplitude is about one-third and the vibratory force is about three times that of a lateral drive system operating at the same power level, resulting in an impedance value about nine times that of the lateral drive system Since the density of the material being welded determines the load impedance, the Wedge-Reed System provides a better impedance match to a metal weldment than a lateral drive system because most metals are six to nine times more dense than plastics.

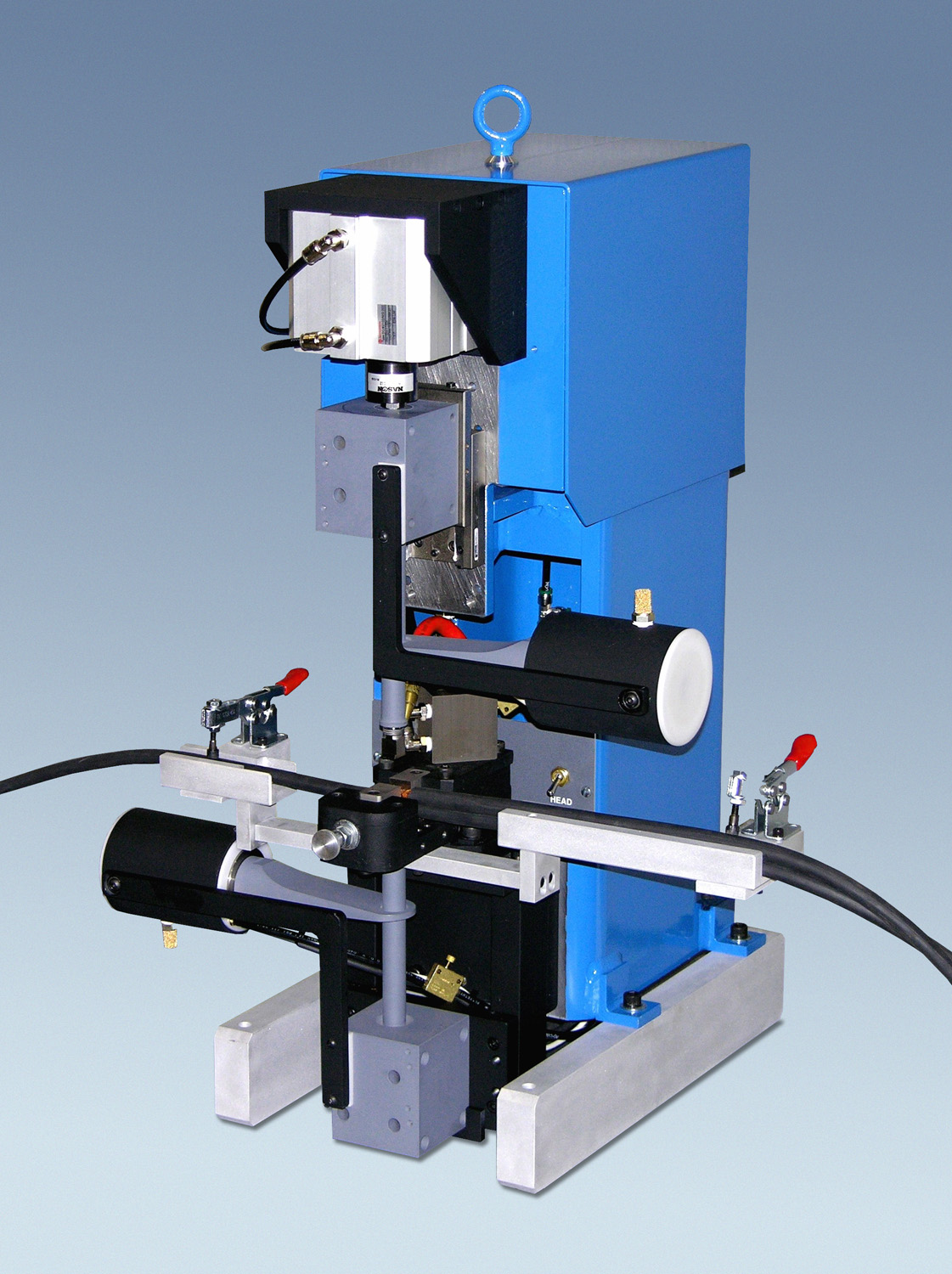

Sonobond offers a variety of ultrasonic welders that handle a range of wire bundle sizes starting at one sq. mm. Its SpliceRite units provide one-pulse wire splicing of up to 100 mm2 in stranded bare copper wire and tinned wire to 60mm2. Its SonoWeld and Dual Head Spot Welders can be custom-tooled to suit special configurations such as wire to terminal applications. Sonobond’s equipment also welds tinned wire to other bare and coated wires or terminals, completing most assemblies in less than one second with minimal operator training.

All machines feature a microprocessor controller that can program welds by height, energy or time, and store and recall up to 250 jobs. Plus, all units have heat-treated, taper-lock tips that are able to be redressed and can produce up to 100,000 welds before being discarded. They’re easily replaceable without requiring machine readjustment or calibration. Additionally, Sonobond equipment offers automatic frequency control and overload protection, and can detect and prevent wrong-part or no-part welding when equipped with an optional distance measuring device.

Click here for more information on Sonobond.