Battery Power’s Senior Editor, Shannon Given, had the opportunity to interview Pat Trippel, the recently announced CEO of Inventus Power. Inventus Power is the is the largest vertically integrated power systems manufacturer in the US and produces custom battery solutions for medical, military, commercial and consumer markets in nine countries across the globe. Read more about Q&A with Inventus Power CEO Pat Trippel …

Category: Articles

Battery Diagnostics On-the-Fly: Removing the “Black-Box” Stigma by Making Performance Transparent

Isidor Buchmann, CEO & Founder, Cadex Electronics, Inc.

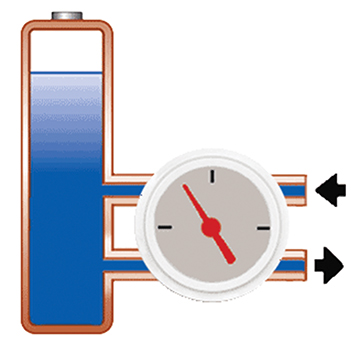

Battery users imagine a battery pack being an energy storage device that resembles a fuel tank dispensing liquid fuel. For simplicity reasons, a battery can indeed be perceived as a vessel storing electrical energy; however, measuring energy flowing into an electrochemical device and then drawing it out again is far more complex than handling liquid fuel. While a hydraulic fuel gauge measures liquids moving in and out of a tank of known size, a battery fuel gauge reads units of current. Battery size is specified in ampere hours (Ah), and what makes estimating battery state-of-charge (SoC) and state-of-health (SoH) so challenging is an unsteady state; a battery loses capacity with each charge and leaks energy in the form of self-discharge. Read more about Battery Diagnostics On-the-Fly: Removing the “Black-Box” Stigma by Making Performance Transparent …

Q&A with Inventus Power CEO Pat Trippel

Battery Power’s Senior Editor, Shannon Given, had the opportunity to interview Pat Trippel, the recently announced CEO of Inventus Power. Inventus Power is the is the largest vertically integrated power systems manufacturer in the US and produces custom battery solutions for medical, military, commercial and consumer markets in nine countries across the globe. Read more about Q&A with Inventus Power CEO Pat Trippel …

Improve Tab to Terminal Connections in Battery Pack Manufacturing

Geoff Shannon, Amada Miyachi America, Inc.

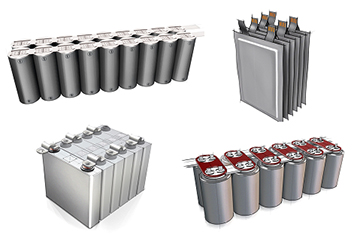

Battery packs have become an integral part of everyday life, powering a growing range of portable electronic devices, cordless power tools, energy storage, and hybrid and electric vehicles. Tab to terminal connection welding is one of the key battery pack manufacturing applications. Manufacturers need equipment, systems, and automated lines that meet quality and production requirements for these products. Both resistance and laser products are well suited to integration into production lines that may be either standalone or automated operation. To maintain the required throughput that offers high quality and yields, users must have a clear understanding of which process is best for the particular battery pack size, tab and terminal material, type, and thickness. In addition, the selected process and integration solution should include process monitoring, process data management, and weld quality assessment. Read more about Improve Tab to Terminal Connections in Battery Pack Manufacturing …

Improve Tab to Terminal Connections in Battery Pack Manufacturing

Geoff Shannon, Amada Miyachi America, Inc.

Battery packs have become an integral part of everyday life, powering a growing range of portable electronic devices, cordless power tools, energy storage, and hybrid and electric vehicles. Tab to terminal connection welding is one of the key battery pack manufacturing applications. Manufacturers need equipment, systems, and automated lines that meet quality and production requirements for these products. Both resistance and laser products are well suited to integration into production lines that may be either standalone or automated operation. To maintain the required throughput that offers high quality and yields, users must have a clear understanding of which process is best for the particular battery pack size, tab and terminal material, type, and thickness. In addition, the selected process and integration solution should include process monitoring, process data management, and weld quality assessment. Read more about Improve Tab to Terminal Connections in Battery Pack Manufacturing …

Adaptive Charging: Extending Battery Life and Reducing Costs in Mission Critical Telecommunications Standby Systems

Alex Rawitz, Business Development Manager, Servato

The accelerating growth of Internet of Things (IoT) devices and applications require continuous investment in telecommunications networks to provide the connectivity for millions of new devices. As more devices connect to the Internet, service outages become more impactful to the people and businesses that rely on IoT applications. Safeguarding telecom networks from power outages is the Valve Regulated Lead Acid (VRLA) battery. Stationary VRLAs are ubiquitously used at broadband, wireless and cable sites, and millions are in service across the country. Unfortunately, almost all of these batteries, and thus the sites that depend on them, are vulnerable to a reliability-damaging standard: float charging. While float charging will maintain batteries at full charge, it can have a damaging impact on the service life of the battery, which introduces risk and increases maintenance costs. There is a better way to charge batteries, Adaptive Charging, that mitigates the degrading effects of float charge, extending battery life and reducing maintenance costs. Read more about Adaptive Charging: Extending Battery Life and Reducing Costs in Mission Critical Telecommunications Standby Systems …

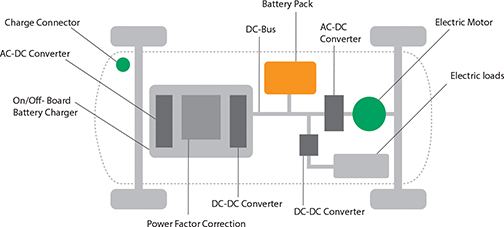

Sorting Busbar Choices for Electric Vehicle Power Distribution

Dominik Pawlik, Technical Marketing Manager

Rogers Corp., Power Electronics Solutions (PES)

Interest in electric vehicles (EVs) and hybrid electric vehicles (HEVs) is growing steadily as battery technologies improve and the driving range of such vehicles increases. Perhaps as important, EVs/HEVs offer a “green” alternative to traditional vehicles powered by internal-combustion gasoline engines. Read more about Sorting Busbar Choices for Electric Vehicle Power Distribution …