Isidor Buchmann, CEO & Founder, Cadex Electronics, Inc.

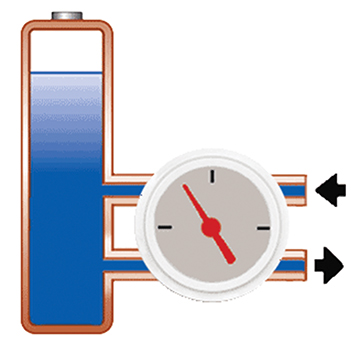

Battery users imagine a battery pack being an energy storage device that resembles a fuel tank dispensing liquid fuel. For simplicity reasons, a battery can indeed be perceived as a vessel storing electrical energy; however, measuring energy flowing into an electrochemical device and then drawing it out again is far more complex than handling liquid fuel. While a hydraulic fuel gauge measures liquids moving in and out of a tank of known size, a battery fuel gauge reads units of current. Battery size is specified in ampere hours (Ah), and what makes estimating battery state-of-charge (SoC) and state-of-health (SoH) so challenging is an unsteady state; a battery loses capacity with each charge and leaks energy in the form of self-discharge.

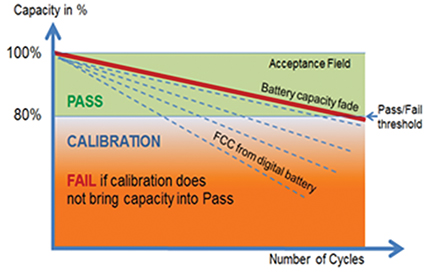

The specified capacity of a new battery is (should be) 100 percent; replacement is typically at 80 percent. A standard fuel gauge only shows SoC; capacity is not revealed. A full charge lights up the entire SoC scale, even if the capacity has faded to 50 percent and delivers only half the runtime.

Estimating battery SoC is commonly done by coulomb counting. The theory goes back 250 years when Charles-Augustin de Coulomb first established the “Coulomb Rule.” It consists of units of electric charge in which one coulomb (1C) equals one ampere (1A) for 1 second. Figure 2 illustrates the principle of in and outflowing currents representing coulomb counting.

Coulomb counting should be flawless but tracking errors occur. If, for example, a battery was charged for one hour at 1 ampere, the same amount of energy should be available on discharge. No battery can do this. Inefficiencies in charge acceptance, especially towards the end of charge and particularly if fast-charged, reduces the energy efficiency. Losses also occur in storage and during discharge. The available energy is always less than what has been fed into the battery.

Coulomb counting becomes part of a battery management system (BMS) that also assists in controlling mobile phone and laptop batteries. Furthermore, a BMS keeps the battery voltage and current in check to maintain safety and prolong battery life.

The user of a new gadget is usually inclined to trust a fancy fuel gauge graphic. A false sense of security may develop but this trust is dashed when the runtimes get shorter with each charge as the device ages. For the casual user of a mobile phone or laptop, a fuel gauge error is only a mild irritant. The problem escalates with medical and military devices, as well as with drones and electric drivetrains that depend on precise range predictions.

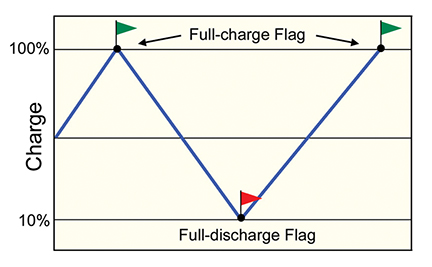

To maintain fuel gauge accuracy, a smart battery should periodically be calibrated by discharging it until the “Low Battery” symbol appears on the device. This can be done in the device. A full cycle sets the respective flags as shows in Figure 3. A linear line forms between these two anchor points to allow reasonably accurate SoC estimations for a time.

How often should a battery be calibrated? This depends on the application. A battery in continued use should be calibrated every three months or after 40 partial cycles. If the device applies a periodic full deep discharge, then calibration should not be needed. A user’s manual for an Apple iPad reads: “For proper reporting of SoC, be sure to go through at least one full charge/ discharge cycle per month.” What happens if the battery is not calibrated regularly? Can such a battery be used with confidence? The battery should function normally and there are no safety concerns, but the digital SoC readout becomes unreliable.

When designing a BMS, engineers often make the mistake of assuming that a battery will always stay young. As with us folks, batteries age and this is manifested in capacity loss. The SoC gauge will always show a glowing 100 percent after each charge. Capacity is conveniently hidden from the user. Several methods to estimate battery state of health (SoH) exist and are in development.

This article describes five technologies, including:

• Coulomb counting as part of an integral battery system in mobile phones and laptops

• Reading the FCC register in an System Management Bus (SMBus) battery

• Adding Read-and-charge(RAC) to a charger

• Rapid-tests by taking a snapshot of the “chemical battery”

• Traditional full cycle.

Coulomb Counting

Some mobile phones and laptops come with software that estimates SoH. This is done by coulomb count, but service technicians familiar with such systems say that the readings are not reliable. Part of this arises from inaccuracies in measuring discharge current when running different applications. The load is pulsed and not all mobile phones allow current measurement. This prevents the use of the capacity app in such cases.

Coulomb counting is also used to estimate the capacity of e-bikes. Although carefully monitored, the SoH readings are not revealed to the user. For reasons of anonymity, only authorized personnel have access by a security code. Device manufacturers fear that showing a capacity of less than 100 percent would raise too many consumer complaints, especially during the warranty period. Such secrecy typically only applies to consumer products; industrial applications differ.

SoC of a portable device is usually shown in percentage or in runtime minutes; the EV does this with driving range in kilometers or miles. A true assessment in Ah, as is possible with a tank of gasoline in a vehicle is not possible with the battery. The amount of Ah a battery can capture as it ages goes into hiding. Consumer concerns aside, knowing battery capacity has the benefit of connecting Ah with runtime and predicting battery replacement on capacity, the leading battery health indicator.

Reading the FCC Register in an SMBus Battery

Chargers are advancing and will soon offer battery SoH readouts. As industries switch to the SMBus battery, FCC (full charge capacity) stored in the battery can interpret SoH by the coulomb count taken while the battery is in service. This allows checking SoH by simply inserting the battery into a charger. The SMBus battery has a further advantage of providing a digital serial number that will enable storing historic battery performance information in a database.

If the FCC reading in such a charger is above the user-set Pass/Fail threshold, then the battery will pass; if below, calibration is needed. Calibration applies a full charge and discharge cycle to reset the flags and ascertain the true capacity of the “chemical battery.” If the capacity is above target, then the battery passes and the FCC reading is corrected; results below the line calls for a battery replacement. Digital FCC peripherals are normally lower than the actual battery capacity and this prevents a false positive result. Figure 3 demonstrates the concept in graphics. Cadex is developing a charger line that encompasses this feature under the Universal Diagnostic Charger (UDC) series.

Read-and-Charge (RAC)

The UDC chargers in development will also feature a new Read-and-charge (RAC) diagnostic to estimate battery capacity more accurately. Inserting a Li-ion battery, the RAC charger determines the residual SoC with a proprietary algorithm and then measures the inflowing coulombs to fill the battery. Combining the coulomb count with residual charge gives the full capacity. An analogy is topping a partially filled bottle by calculating the added amount. The bottle size represents 100 percent; what it can hold reflects the capacity.

RAC requires a one-time calibration for each battery model. Cycling a good battery provides the reference reading that can be stored in the charger. The RAC charger has the ability to estimate the capacity of a regular (dumb) battery. Tests are showing better accuracies with RAC than what is possible with the FCC capture of an SMBus battery. RAC validates battery performance and does quality control with no extra logistics. The green “ready” light at the end of service assures that the battery is fully charged and meets the required capacity threshold. A faded battery is identified and shown the backdoor.

Rapid-Test

The Rapid-test takes a snapshot of a chemical battery in seconds or minutes. Electrochemical Dynamic Response uses pulse technology; the more complex Multi-model Electrochemical Impedance Spectroscopy (Spectro) scans the battery with multiple frequencies. Rapid-tests have the advantage of testing a broad range of batteries without smarts on the fly, but this requires complex software and hardware that is supported by battery-specific parameters and matrices.

It is important to note that the capacity of a battery cannot be measured similar to voltage, current and temperature. SoH can be estimated to various degrees of accuracy based on its symptoms; however, a reliable measurement is not possible if the symptoms are vague or not present.

Many makers of battery test devices promise capacity estimation by measuring the internal battery resistance. This is misleading and advertising features that are outside the equipment’s capabilities confuses the industry into believing that complex tests can be done with basic methods. Resistance-based instruments can indeed identify a dying or dead battery, so does the user. Battery testers are often overstated similar to promoting a shampoo that promises to grow lush hair on a man’s bald head.

Full Cycle

This method applies a full charge/discharge cycle to read the capacity of the chemical battery. The time discharging a battery with a regulated discharge current determines the capacity. Although accurate and also serving as calibration of a smart battery, a full cycle is time consuming and is not always practical, especially when checking mobile phone batteries.

Philosophy and Conclusion

Many device manufacturers do not provide sufficient guidelines on battery maintenance and the user is ill-informed on battery performance and when to replace a fading battery. There is a “hand-washing” when passing a device to the workforce, saying, “You are on your own — good luck with the battery.”

Developing a better battery is incomplete without improving the diagnostics. Only a well-designed diagnostic system that monitors state-of-function (SoF) will turn the battery into a reliable, safe, cost efficient and environmentally sustainable power source. The modern battery will interact with system and user, state its needs, proclaim what it can deliver and establish definite limitations.

Isidor Buchmann is the founder and CEO of Cadex Electronics Inc. For three decades, Buchmann has studied the behavior of rechargeable batteries in practical, everyday applications, has written award-winning articles including the best-selling book “Batteries in a Portable World,” now in its fourth edition. Cadex specializes in the design and manufacturing of battery chargers, analyzers and monitoring devices.

For more information on batteries, visit www.batteryuniversity.com; product information is on www.cadex.com.