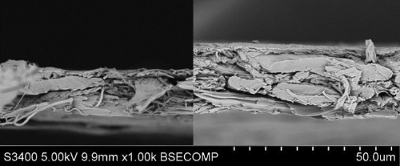

Dreamweaver International has developed patented technology that will allow it to make the thinnest nonwoven separators in the world for lithium ion batteries and supercapacitors, as low as 10 to 12 microns. The technology relies on lighter weights and much higher compression than other nonwoven battery separators. The innovation will allow the traditional benefits of nonwoven separators, enhanced safety at a low cost, to be delivered at a thickness that is optimum for traditional lithium ion battery separators. The thickness is ½ the thickness of the dominant products in the supercapacitor industry.

“This is a game changer for supercapacitors,” said Stephen Voller, CEO of ZapGoCharger Ltd. “The thickness reduction will complement our industry-leading energy density, making our supercaps even more competitive with batteries. Perhaps the most important part is that the cost per farad will decrease because of significantly reduced use of expensive electrolyte. I would be surprised if the entire industry did not switch within a few years.”

“Separator is an important component in supercapacitors,” said Dr. Lin Cao, General Secretary of China Supercapacitor Standard Committee, “Technological advances for lighter and thinner separators with improved safety and stability are critical to drive developments and applications of the industry. They are also key elements to increase energy density and reduce the cost.”

Dreamweaver has prototypes for a 15 micron Titanium product developed for the supercapacitor industry, and a 20 micron Silver product developed for t the lithium ion battery market. The products will be produced by Glatfelter, Dreamweaver’s production partner. Products as low as 10 to 12 microns thin will follow.

“We have listened to our customers, who were demanding low thickness, low pore size and high strength while continuing to value the safety characteristics and low cost of Dreamweaver’s current products,” said Brian Morin, President & COO of Dreamweaver International.