Commentary Contributed by O. El Baradai, J. Schleuniger*, S. Fricke, C. Bosshard, CSEM SA, Switzerland

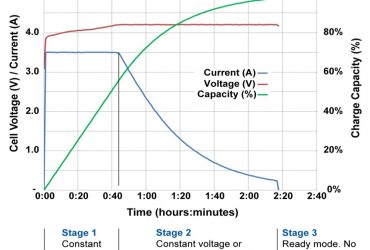

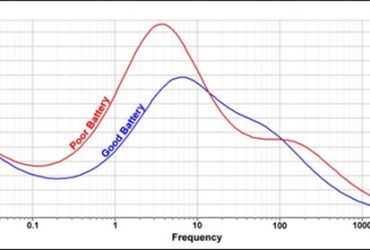

October 24, 2017 | Continuous progress in electronic devices, in particular portable electronic gadgets, is creating new opportunities and products to revolutionize our daily life. However, these ubiquitous portable devices with different functions require highly efficient power sources to sustain their use. Batteries are essential for powering such portable electronic devices. A battery is a closed system in which energy is stored in chemical form, and it is converted to electrical energy by connecting the battery to an external load to complete the circuit, causing electric current to flow between the anode and cathode. Electronics have traditionally been designed around commercial batteries:prismatic, cylindrical, and coin cells, which are bulky, rigid, and non-flexible, making them unsuitable for powering flexible electronics. Read more about Printed and Bio-Sourced Lithium Ion Batteries for Wearable Technologies …