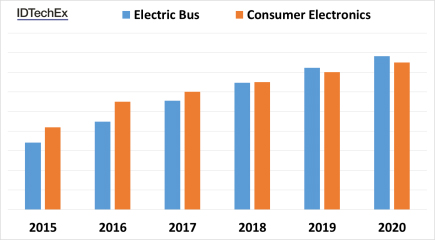

The electric bus (e-bus) market is growing at a CAGR of 20 percent in terms of unit sales. The rapid growth is a game changer for the battery market as electric buses require large-sized batteries ranging from 74 kWh (fast charging e-bus) to over 300 kWh (slow charging e-bus). This is why IDTechEx Research forecasts that the e-bus battery market will overtake the consumer electronics sector by 2020. Indeed, the IDTechEx Research report “Lithium-ion Batteries for Electric Buses 2016-2026” predicts large e-bus battery market will grow to $30 billion by 2026, potentially making it the largest segment of the overall battery market (Figure 1).

This prospect is defining the battle lines in the battery value chain. Indeed, we expect that this sector will alter the entire value chain for battery production from material suppliers, battery manufacturers through to original equipment manufacturers (OEMs).

China is currently the world leader in electric buses since 97 percent and 75 percent of electric buses and their batteries are produced in the country, respectively. China is seeking to dominate the battery market by retaining the entire value chain of electric vehicles and batteries within the country. Indeed, there has been recent news about the Chinese government intervention with regards to the nickel manganese cobalt (NMC) lithium-ion variant, which is produced exclusively outside the country.

This smells of short-term protectionism since lithium iron phosphate (LFP) variant is the most common chemistry manufactured in China and used in Chinese e-buses. It is uncertain whether this intervention by the Chinese government will ultimately be upheld but what is certain is that it at least acts as a short-term break on the market of non-LFP batteries.

This policy will naturally favour domestic battery manufacturers such as BYD and Lishen who largely supply the LFP battery technology to electric bus manufacturers. Battery giants in Japan and Korea who manufacture the NMC battery chemistry for electric buses such as Toshiba, LG Chem and Samsung are most likely to be adversely affected by this intervention.

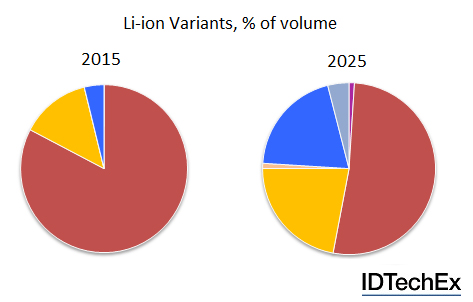

Safety is a critical requirement, especially in large-sized batteries for electric buses. This is partly why the LFP chemistry has come to dominate the market today, controlling over 80 percent of the market. This is in contrast to the electric car market where the battery supplier market share is more mixed and balanced between many different chemistries. In addition, the IP landscape for LFP is also more open and accommodating, removing one of the key non-capital barriers into this market and opening the way for new entrants.

This LFP chemistry however suffers from low energy density (90 to 120 Wh/kg) and slow charging rate (average of 4 hours in slow charging e-buses) when compared with NMC. This is why NMC suppliers are hoping to use advanced battery management systems to match LFP’s safety levels, thus creating superior batteries. NMC suppliers are also located outside China and will initially target the non-Chinese market.

IDTechEx Research believes that these and similar trends will help create a more diverse market composition as non-LFP technologies will also penetrate the market. As shown in Figure 2 below, IDTechEx Research predicts that for the business-as-usual scenario the non-LFP battery technology will grow to 48 percent of the market in 2025, making the e-battery bus business a truly global market. This may help explain why China is keen to intervene. Indeed, if the Chinese government rigorously applies its policy on non-LFP batteries the market dynamics will completely change in favour of LFP. We also forecast this scenario in our report. More information on the forecast considering the Chinese intervention can be found in the IDTechEx Research report “Lithium-ion Batteries for Electric Buses 2016-2026”.

The report from IDTechEx Research “Lithium-ion Batteries for Electric Buses 2016-2026” gives an in-depth market analysis on the dynamics of lithium-ion batteries currently used in electric buses and provides forecast on future developments and market share for the different lithium-ion chemistries. The report covers the main lithium-ion variants used in electric buses (under 8 ton and over 8 ton hybrid and electric buses), demand and sales forecast from 2016 to 2026, market share and size and key players in the battery and electric bus industry. The report also discusses the role of other energy storage systems such as supercapacitors, lithium capacitors, fuel cells, advanced and post lithium batteries and flywheels and how they would affect the battery market for electric buses.